I am taking care of a number of Sportident units, which are used in the sport of orienteering. These are small embedded systems powered by non-rechargeable lithium batteries, specifically thionyl chloride (Li-SOCl2) batteries, and every few years the batteries need to be replaced, depending on how much the unit has been used. The units themselves tries to keep track of the battery status by dead reckoning and by measuring the battery voltage, apparently while it is doing something that consumes current. The state of the battery voltage under load can be read out as can the value of the estimated remaining capacity.

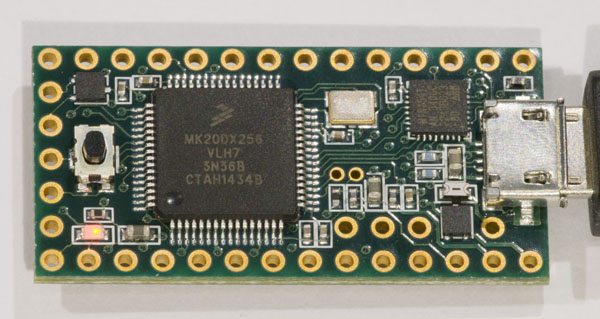

To help in determining the status of such batteries, I wanted to have a device that could measure the voltage and the internal resistance in a convenient manner. I had a Teensy laying around and since it has a DAC output and several analog inputs, it looked like a good platform to quickly hook something together that could do the task.

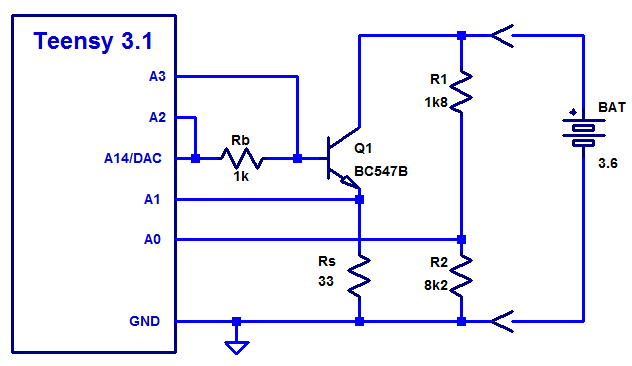

This is the schematics I came up with:

The circuit works like this:

R1 and R2 forms a voltage divider that reduces the battery voltage to below 3.3 V which is the limit of the ADC of the Teensy. Q1 and Rs forms a current sink controlled by the voltage on the A14/DAC pin. Basically the DAC pin sets the base voltage and since the base-emitter voltage is fairly constant, a constant voltage will develop over the emitter resistor Rs. To maintain this voltage Q1 will conduct as much current as required from the battery. The emitter current can be measured by measuring the voltage drop across Rs using analog input A1.

The purpose of having A2 and A3 connected across the base resistor is to be able to measure the (small) base current so that it can be subtracted from the emitter current when calculating the battery current. This is only a small correction and not really important, but since the inputs were available and it was easy to do, I added this little feature.

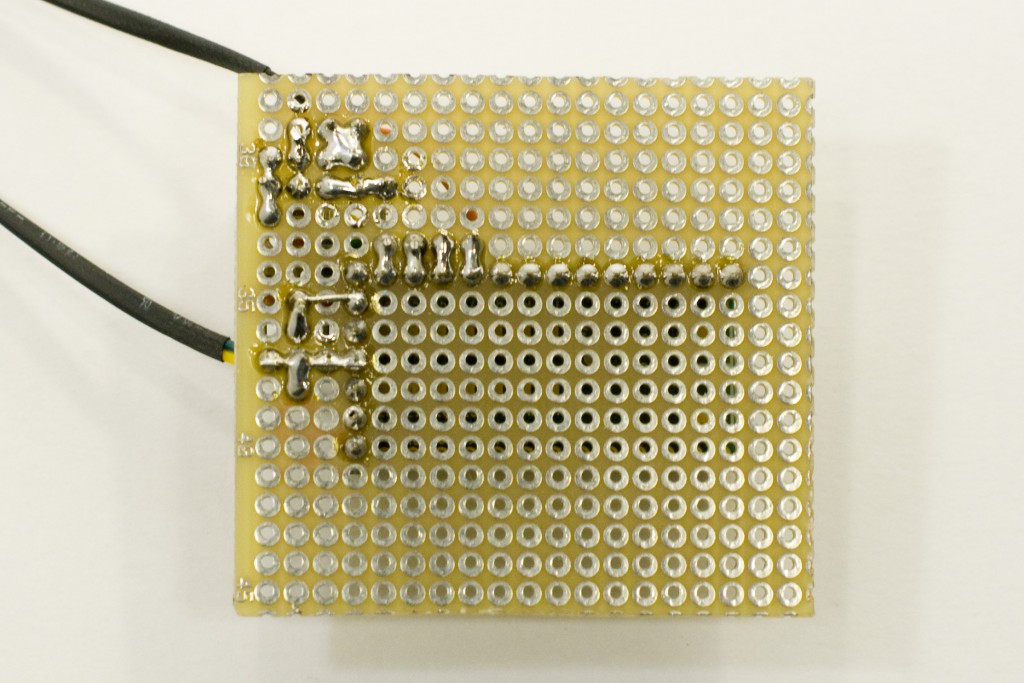

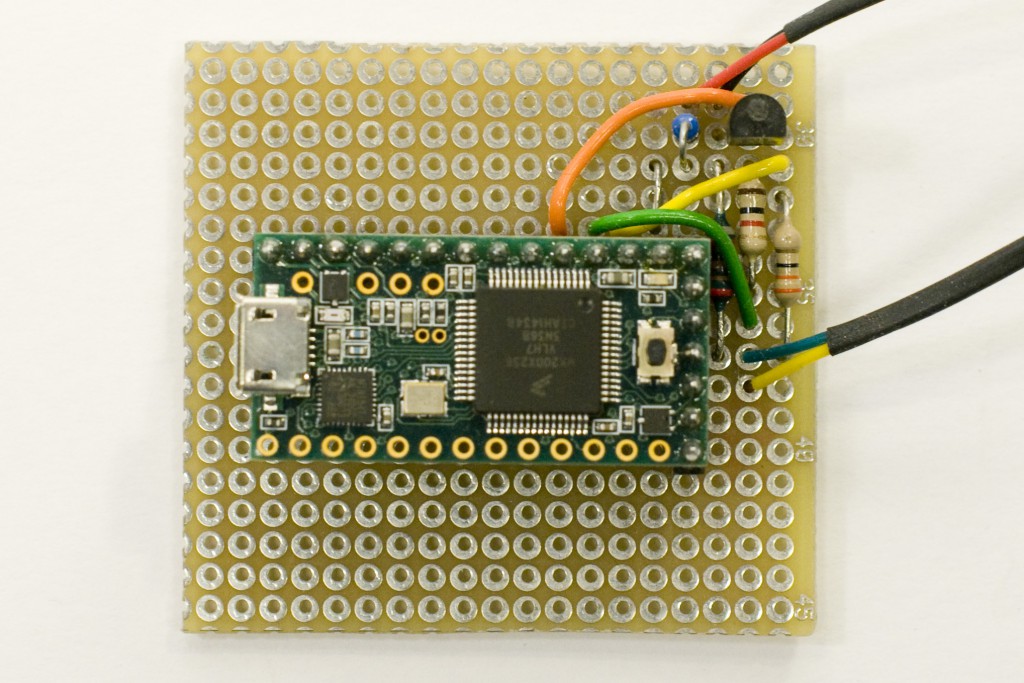

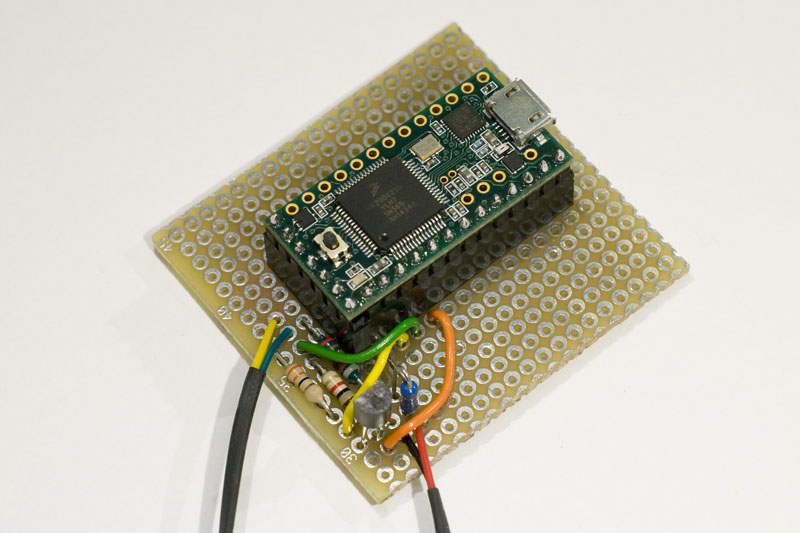

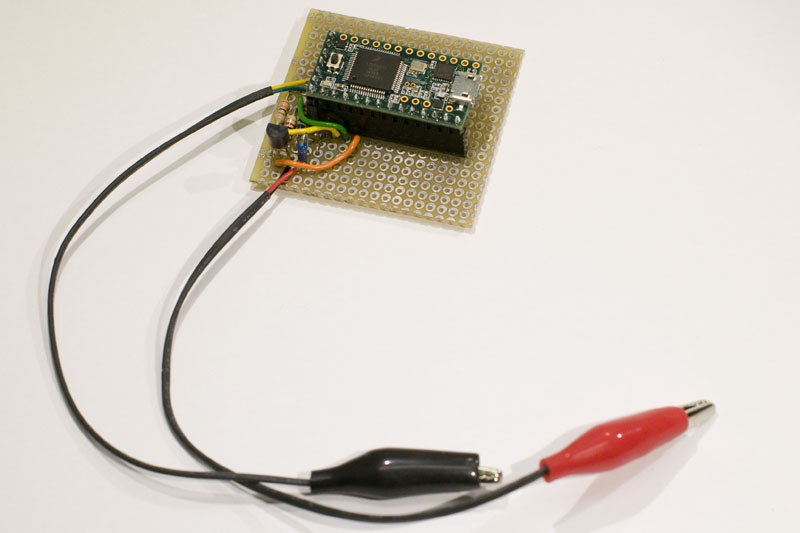

I built the physical circuit on perfboard and it looks like this:

As can be seen, the whole thing is very simple to build as the Teensy does all the heavy lifting.

I did of course need a program to control the whole thing and do all the measuring, calculations and presentation of results. This is the program I came up with:

/* Lithium battery tester

Tests the internal resistance of a small 3.6 V lithium battery by ramping up the load current and measuring

the pole voltage and calculating the internal resistance.

Written by Per Magnusson, http://www.axotron.se

v 0.1 2015-05-24

This program is public domain.

*/

const float Rtop = 1817; // Top resistor of divider, ohms

const float Rbot = 8170; // Bottom resistor of divider, ohms

const float Rs = 32.8; // Current sense resistor, ohms

const float Rb = 995; // Base resistor, ohms

const float Vref = 3.3; // ADC reference voltage, volts

const int ADCbits = 12;

const int DACbits = 12;

const float voltPerADC = Vref/((1<<ADCbits) - 1.0); // Factor to convert ADC codes to volts

const float voltPerDAC = Vref/((1<<DACbits) - 1.0); // Factor to convert DAC codes to volts

const float DACperVolt = 1/voltPerDAC; // Factor to convert volts to DAC codes

const int detectLimit = 0.8/voltPerADC; // Limit for detecting battery

const float curLim = 35.0e-3; // Maximum test current in A

const float curStep = 5.0e-3; // Target current step

const int maxIter = 3; // Number of iterations to reach target current

const int vsensePin = A0; // Voltage sense pin

const int curSensePin = A1; // Emitter current sense pin

const int baseSenseHiPin = A2; // High base current sense pin

const int baseSenseLoPin = A3; // Low base current sense pin

const int dacPin = A14; // Current control pin

const int ledPin = 13; // LED for debug

const byte sWaitNoBat = 0;

const byte sWaitBat = 1;

byte state;

void setup() {

Serial.begin(57600);

analogWriteResolution(DACbits);

analogReadResolution(ADCbits);

analogWrite(dacPin, 0);

pinMode(ledPin, OUTPUT);

state = sWaitNoBat;

Serial.println("Battery tester");

digitalWrite(ledPin, HIGH); // turn LED on

delay(3000);

digitalWrite(ledPin, LOW); // turn LED off

Serial.println("Waiting for a battery to be connected...");

}

void loop() {

int voltCode;

int baseVoltCode;

int curCode;

int dacVal;

int dacStep;

float volt;

float voltNoLoad;

float curNoLoad;

float cur;

float baseCur;

float res;

float prevCur;

float targCur;

float stepCur;

byte testBat;

byte iter;

analogWrite(dacPin, 0); // Make sure we are not loading the battery in this state

testBat = false;

voltCode = analogRead(vsensePin); // Read battery voltage to see if it is connected

if(state == sWaitNoBat) {

// We are waiting for at battery to be connected

if(voltCode > detectLimit) {

// A battery was connected

testBat = true; // Proceed to test it

}

} else if(state == sWaitBat) {

// We are waiting for a battery to be disconnected

if(voltCode < detectLimit) {

// A battery was disconnected

Serial.println("\nWaiting for a battery to be connected...");

delay(1000); // Delay to not react on glitches while the battery is being disconnected

state = sWaitNoBat;

}

}

if(!testBat) {

// Not in a situation that a battery should be tested

return;

}

// Test the battery

Serial.println("Battery connected, waiting for connection to stabilize.");

delay(1000); // Wait for the connection to stabilize

voltCode = analogRead(vsensePin);

if(voltCode < detectLimit) {

// The battery is gone, it was just a glitch

state = sWaitNoBat;

Serial.println("Battery removed, aborting.");

Serial.println("Waiting for a battery to be connected...");

return;

}

digitalWrite(ledPin, HIGH); // turn LED on

Serial.println("Testing battery.");

voltNoLoad = voltCode * voltPerADC * (Rtop+Rbot)/Rbot;

volt = voltNoLoad;

curNoLoad = voltNoLoad/(Rtop+Rbot); // "No load" current

Serial.println("");

Serial.print("Unloaded voltage: ");

Serial.print(voltNoLoad);

Serial.print(" V (current = ");

Serial.print(curNoLoad*1000);

Serial.println(" mA)");

// Ramp up the current

cur = 0;

targCur = 0;

dacVal = 0.66*DACperVolt; // Base drive starting value, 0.66 V, low current

dacStep = 5.0e-3*Rs*DACperVolt; // Increment ~5 mA per iteration

prevCur = 0;

iter = maxIter; // First step is to read whatever current the starting DAC value results in

// Loop to set a number of different battery test load currents and measure the battery performance at each current

while(1) {

if(targCur > curLim) {

// We are beyond the maximum target current, normal exit from loop

break;

}

if(dacVal >= (1<<DACbits)) {

// The DAC value is too big, exit from loop

Serial.print("Warning: Above maximum DAC setting (");

Serial.print(dacVal);

Serial.println("), exiting");

break;

}

analogWrite(dacPin, dacVal); // Drive the base of the transistor

delay(10);

voltCode = analogRead(vsensePin); // Battery voltage reading

volt = voltCode * voltPerADC * (Rtop+Rbot)/Rbot; // Calculate battery voltage

baseVoltCode = analogRead(baseSenseHiPin) - analogRead(baseSenseLoPin); // Read voltage drop across base resistor

baseCur = baseVoltCode * voltPerADC/Rb; // Calculate base current

curCode = analogRead(curSensePin); // Emitter current reading

// Calculate battery current and compensate for base current and divider current

cur = curCode * voltPerADC/Rs - baseCur + curNoLoad;

if(voltCode < detectLimit) {

// The voltage is too big, exit from loop

Serial.print("Warning: Below minimum battery voltage (");

Serial.print(volt);

Serial.println(" V), exiting");

break;

}

if((cur - curNoLoad) > 0) {

res = (voltNoLoad - volt)/(cur - curNoLoad); // Calculate internal resistance

} else {

res = 0; // Avoid dividing by zero

}

if(iter < maxIter) {

// Make a small adjustment to get closer to the target current

if(cur != prevCur) {

dacVal += dacStep*((targCur-cur)/(cur-prevCur));

}

iter += 1;

} else {

// Print result

Serial.print("Voltage: ");

Serial.print(volt);

Serial.print(" V");

Serial.print(" Current: ");

Serial.print(cur*1000);

Serial.print(" mA");

Serial.print(" Resistance: ");

Serial.print(res);

Serial.println(" ohms");

// Move to next target current

targCur += curStep;

if(prevCur > 0 && (cur-prevCur > 0)) {

// Estimate the step size required to reach the next target current

dacStep = dacStep*((targCur-cur)/(cur-prevCur));

}

dacVal += dacStep;

prevCur = cur;

iter = 0;

}

if(cur > curLim*1.2) {

// The current is too big, exit from loop

Serial.print("Warning: Maximum current exceeded (");

Serial.print(cur);

Serial.println(" mA), exiting");

break;

}

}

analogWrite(dacPin, 0); // Stop the battery current drain

digitalWrite(ledPin, LOW); // turn LED off

state = sWaitBat;

Serial.println("Done");

Serial.println("Disconnect battery.");

}

The program sends information to a serial terminal (I used the one inside the Arduino development environment). It waits for a battery to be connected and then ramps up the current and reports the pole voltage as well as the internal resistance at a couple of different load currents. This is what the output can look like:

Waiting for a battery to be connected... Battery connected, waiting for connection to stabilize. Testing battery. Unloaded voltage: 3.67 V (current = 0.37 mA) Voltage: 3.63 V Current: 1.39 mA Resistance: 39.36 ohms Voltage: 3.47 V Current: 4.97 mA Resistance: 41.95 ohms Voltage: 3.27 V Current: 9.99 mA Resistance: 41.26 ohms Voltage: 3.08 V Current: 15.03 mA Resistance: 40.23 ohms Voltage: 2.89 V Current: 19.98 mA Resistance: 39.33 ohms Voltage: 2.72 V Current: 24.97 mA Resistance: 38.56 ohms Voltage: 2.54 V Current: 29.99 mA Resistance: 37.88 ohms Voltage: 2.37 V Current: 34.99 mA Resistance: 37.33 ohms Done Disconnect battery.

With a different program, the circuitry can of course also be used to test batteries in different ways.

Update on 2015-10-11

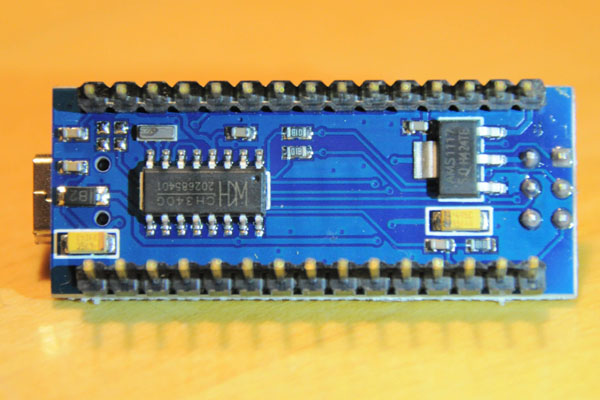

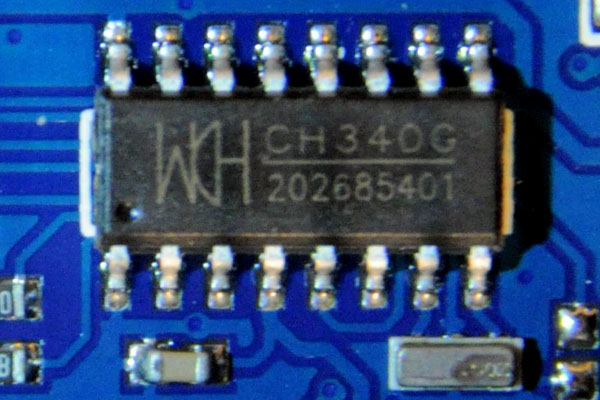

As requested by Alex in the comments, here is a picture of the bottom side of the board (and the corresponding picture of the top).